Molasses alcohol waste liquid five-effect evaporation device

I. Overview

Molasses alcohol waste liquid is highly corrosive and has high chroma, which is difficult to remove by biochemical method. Concentrated incineration or high-efficiency liquid fertilizer is the most thorough treatment plan at present.

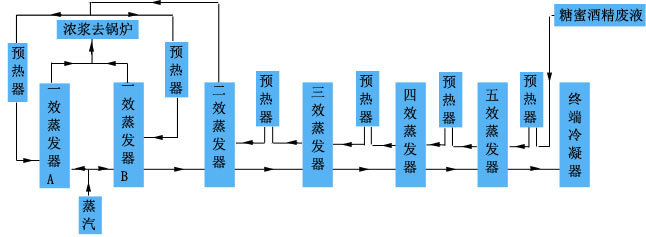

The device adopts a five-effect forced circulation step-down evaporation system, with saturated steam as the heat source, one-effect heating and five-effect work. The molasses alcohol waste liquid with a concentration of 5 to 6% is concentrated and evaporated, and a concentrated slurry having a concentration of ≥ 60% is sent to the boiler for incineration, and the generated heat substantially satisfies the steam for the device. Evaporate the condensed water back to the previous section for dilution water.

Second, the process flow chart

Blob.png

Third, the process characteristics

1. Set the spare evaporator to clear the material, which can realize non-stop cleaning and ensure continuous production.

2. The device adopts automatic program control to save labor costs.

3. High processing efficiency and stable operation

4. By using thick slurry to return to the boiler, molasses can produce alcohol without adding fuel.

In the Next:Aginomoto continuous crystallization process

Service hotline: 0538-3399066;0538-3393566;0538-3393266

Fax: 0538-3399066

Zip code: 271600

Address: Feicheng High-tech Industrial Development Zone, Shandong Province

2022 Shandong Jinta Machinery Group Co., Ltd. All rights reserved.

技术支持:掘金科技