As a Chinese ancient saying goes: One should sharpen his tools before he does the work well. JINTA is equipped with more than 400 sets of top-quality machining and detection equipment with high automation, automatic-control and intelligence together with 16 production workshops, including 5 machining workshops as well as 11 welding and assembly workshops to fully ensure the excellent quality and well-deserved reputation of JINTA Machinery. The company establishes professional ASME equipment and titanium equipment manufacturing workshops to meet non-standardized production demands.

JINTA has been manufacturing stainless steel equipment for 40 years. It owns one experienced team consisting of 16 senior engineers, 54 senior technicians & 200 mechanics above middle level and gains proficiency in manufacturing process of various columns & heat exchangers, surface treatment process, argon arc welding automatic welding for tube sheet orifice, assembling process of column internals and etc., to achieve the best precision and to provide the excellent products to every client.

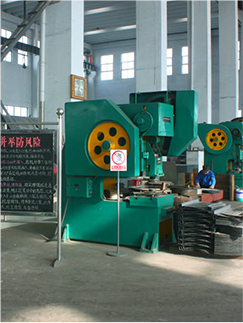

The company is in possession of advanced machining equipment and dedicated mould such as lathe, miller, planer, grinder, boring lathe, drilling press, bending machine, automatic pipe bender, edge planer, CNC plasma cutting machine, CNC wire cut electric discharge machine (NCWEDM), underwater plasma cutting machine, laser cutting machine, automatic submerged-arc welding machine, automatic tube sheet welding machine, Automatic argon arc welding and etc., with which JINTA has manufactured equipment of column, heat exchanger and steel vessel with reliable quality nearly a thousand of clients from home and abroad.

CL526Ai CNC laser cutting machine enjoys high speed and high precision and can finish punching, modeling and blanking primarily; underwater plasma cutting machine is more environmental and more efficient; PLC Control is adopted to CNC lathe and NC machine tools, which is more prompt and convenient and available to program according to production.

laser cutter

Step punch

CNC lathe

CNC lathe

laser cutter

laser cutter

laser cutter

laser cutter

Service hotline: 0538-3399066;0538-3393566;0538-3393266

Fax: 0538-3399066

Zip code: 271600

Address: Feicheng High-tech Industrial Development Zone, Shandong Province

2022 Shandong Jinta Machinery Group Co., Ltd. All rights reserved.

技术支持:掘金科技